What is the material of 100% Virgin Toy Polypropylene

- Categories:100% Virgin Toy Polypropylene News

- Author:

- Origin:

- Time of issue:2023-03-01 14:41

- Views:

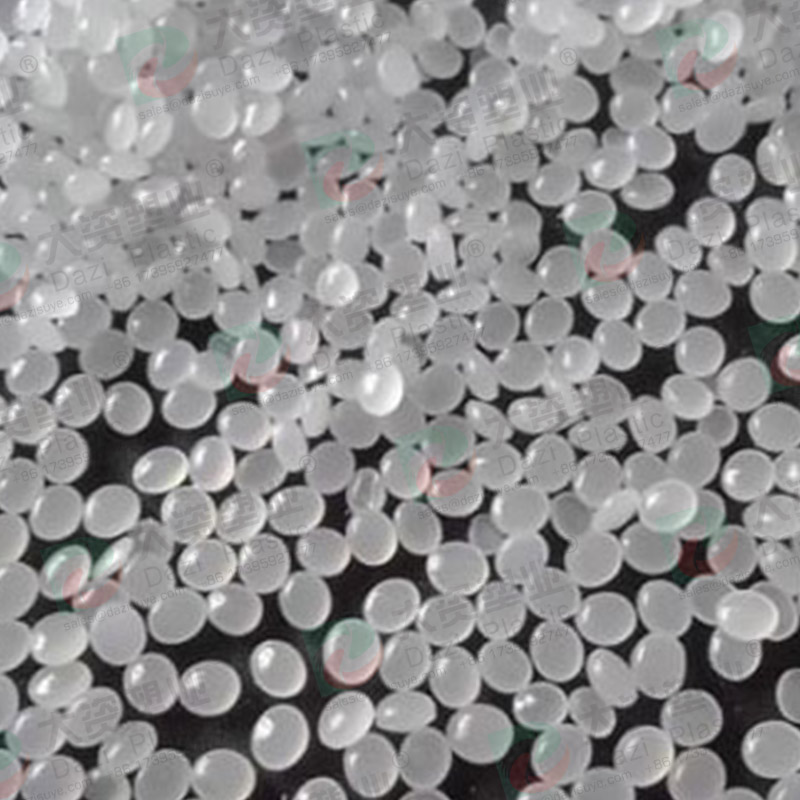

(Summary description)Compared with other general-purpose thermoplastics, 100% Virgin Toy Polypropylene has the advantages of small specific gravity, good rigidity, high strength, bending resistance, heat resistance above 100°C, and good chemical corrosion resistance.

What is the material of 100% Virgin Toy Polypropylene

(Summary description)Compared with other general-purpose thermoplastics, 100% Virgin Toy Polypropylene has the advantages of small specific gravity, good rigidity, high strength, bending resistance, heat resistance above 100°C, and good chemical corrosion resistance.

- Categories:100% Virgin Toy Polypropylene News

- Author:

- Origin:

- Time of issue:2023-03-01 14:41

- Views:

Compared with other general-purpose thermoplastics, 100% Virgin Toy Polypropylene has the advantages of small specific gravity, good rigidity, high strength, bending resistance, heat resistance above 100°C, and good chemical corrosion resistance. The disadvantages of 100% Virgin Toy Polypropylene are poor low-temperature impact resistance, easy aging, and large molding shrinkage.

According to the requirements and uses of the product, 100% Virgin Toy Polypropylene can be modified by blending, filling, reinforcement, adding additives, copolymerization, blending, crosslinking and other methods. For example, calcium carbonate, talcum powder, and minerals can be added to improve hardness, heat resistance, and dimensional stability; glass fibers, asbestos fibers, mica, and glass beads can be added. Improve tensile strength, low temperature impact resistance and creep resistance; add rubber, elastomer and other flexible polymers to improve impact performance and transparency, and various special additives can give 100% Virgin Toy Polypropylene weather resistance and antistatic properties , Flame retardancy, conductivity, electroplating, nucleation, copper damage resistance, etc.

100% Virgin Toy Polypropylene can produce products for different purposes through injection molding, extrusion molding, blow molding, thermoforming, rotational molding, coating, foaming and other processing methods. Since various processing methods have different requirements on the melting performance of 100% Virgin Toy Polypropylene, it has formed injection molding grade, extrusion grade, blow molding grade, coating grade, fiber grade, film grade and rotational molding grade, to Meet different processing requirements.

What's new

Time of issue : 2024-04-30

Time of issue : 2024-04-27

Time of issue : 2024-04-24

Time of issue : 2024-04-21

Have questions? We have answers !

Hi,Create an environmentally friendly production enterprise

Contact us

Tel:0086-0379-67215688

Telphone:+86 17395927477

Email:sales@dazisuye.com

Web:https://www.dazisuye.com

Add:Nanlicun Town Industrial park,xin'an County,luoyang,471800,China

放样式的

放样式的

© Luoyang Dazi Plastic Industry Co., Ltd. Powerby: :300.cn