How to choose a right FIBC bag for your business

- Categories:News

- Author:

- Origin:

- Time of issue:2022-08-24 10:15

- Views:

(Summary description)

How to choose a right FIBC bag for your business

(Summary description)

- Categories:News

- Author:

- Origin:

- Time of issue:2022-08-24 10:15

- Views:

When you are looking for FIBC bags for your business, you need to be able to find the right way to find the right bags. Each type of FIBC bag has its own advantages, especially in the production and application of agriculture, chemical industry, construction and food and beverage industries. When you choose FIBC bags, you must be aware of your products and their storage and transportation methods.This article will give the FIBC bag selection method from several aspects such as size, material, bag type, bagging method, as well as lining and lamination.

Choose right FIBC bags size

When you choose the FIBC bag size, you need to understand the size and weight of your product and how to use theseFIBC bags. If the product needs to be stacked on the pallet after the product is bagged, the size of the bag must be suitable for the size of the pallet, not beyond the edge of the pallet, and not wasting the space of the pallet.

If your product is heavy, the bag you choose must be able to bear great weight without breaking. Proper size bags can reduce product waste, help you create profits, and avoid injuries of relevant personnel due to improper size and overfilling.

When you decide the size of your FIBC bag, you must consider the following two key factors:

1. Density and bagging requirements of your products

2. The size of your existing pallet.

With these figures, you will get the correct FIBC bag that fits your pallets. Once you know the FIBC bag data, you can ask your professional FIBC bag supplier for quotations. They will help you figure out the correct FIBC bag that fits your capacity requirements and pallet size, and at the same time help you improve space utilization.

Types of FIBC bags

FIBC bags material types

The standard categorizing system for FIBC uses letters of the alphabet to indicate the bags’ physical properties and their protection against sparks and electrostatic shocks. These properties are critical because they keep employees safe from electric shocks and minimize the risk of fires and explosions. The categories include:

Type A FIBC bags materials are standard bulk bags, usually made from woven polypropylene, calcium carbonate and UV stabilizer for outdoor protection. These FIBC bags are sturdy, flexible, reliable and cost-effective, although they cannot store combustible products.

Type B FIBC bags materials also contain woven polypropylene, which is very similar to type a bulk bags. However, they have an extra thin coating to prevent sparks.

Type C bulk bags materials usually contain carbon fiber, which can provide protection for flammable powders, but lacks anti-static protection. For safety reasons, when employees move or fill these bags, these bags need to be grounded.

Type D anti-static material in FIBC bags. Suitable for flammable powder, no need to be grounded to prevent electrostatic shock.

These differences are crucial in industries such as the chemical manufacturing industry. Chemical manufacturers often use FIBC bags to transport chemicals, especially dangerous products or products that can generate static electricity. They need FIBC bags, have proper structures, contain safe hazardous products or dissipate static charges, to protect employees from work injuries.

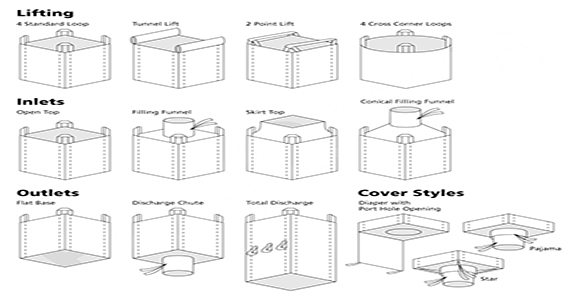

FIBC bag construction styles:

There are several different structural styles for FIBC bags, so you can choose the bag that best suits your unique filling, storage and transportation requirements.

1.Duffle Top FIBC Bags

Duffle top FIBC bags provide attractive flexibility. During the filling process, you can wrap the fabric in different ways to provide speed and safety options, and you can fully open or close the bag as needed. Due to the characteristics of the duffel bag top, these bulk bags are excellent for reducing product loss during storage and transportation.

2.Spout Top FIBC bags

Like the Duffle top FIBC bag, the spout top FIBC bag is to minimize confusion and reduce product loss during storage and transportation.These spouts provide excellent stability during filling, and they are usually the best solution for use with certain types of stationary machinery, especially equipment with discharge hoses.

3.Open Top FIBC bags

Open top FIBC bag is a standard FIBC bag with an open area on it, which provides enough space for manual loading of products. If you need to transport large wood or other construction materials that are not suitable for bags, these bags are good for irregularly shaped objects, for example, they can easily protrude on the top.

These FIBC bags also generate maximum airflow, so they are ideal for perishable agricultural products such as potatoes and onions, which require breathability during transportation and storage. We can also add ventilation strips to the FIBC bag according to customer needs to increase the air permeability of the bags.

4. Baffled FIBC bags

Baffled FIBC bags have rigid panels sewn into each side. These panels keep the bag consistent, sturdy square shape with minimal bulge. Since these bags cannot easily change shape, they usually have a smaller capacity than similar open-top, duffel top or spout top FIBC bags. However, they have great advantages in stacking bags and maximizing storage space. The equipment can hold the bags tightly together to optimize storage and transportation efficiency.

Filling your FIBC bags

When filling FIBC bags, it is necessary to determine a filling method that best suits your workflow, your products and your FIBC bags. With a suitable filling method, you must consider the safety of your workers during the operation.

Here are some precautions when filling your FIBC bags:

1.Filling an empty FIBC bag evenly: Keep your FIBC bag securely upright during the processes of filling and discharging. To fill your FIBC bags from the center. They may topple and fall, and the workers on site may injure by the spills.

2.Close the discharge spouts: Inspecting the output spouts before filling your FIBC bag,and ensure it is closed. It will result in a huge spills if you forgotten this operation.

3.Use every lifting loop: When designing FIBC bags for customers, dazi will give scientific solutions based on customers' products, loading and unloading and transportation methods, so no lifting loop is redundant. In order to ensure that the bag does not have improper weight distribution or tipping over and cause loss of goods and personal injury during use, please ensure that every lifting loops is fully used during bagging, lifting and transportation.

4.Vertical lifting: When designing lifting loops for FIBC bags of dazi, they are all designed according to the lifting method of vertical lifting. In order to prevent the FIBC bag from breaking or affecting the use, please do not lift it horizontally.

In addition to the above aspects, you also need to ensure that your facility has the correct loading equipment. Below are some equipment that may be used to ensure that you fill in safely and effectively.

Stand-alone filling machine: The stand-alone filling machine is the most commonly used type of FIBC mechanical filling equipment. They are ideal in many applications, because of their direct, intuitive design and easy operation, they are particularly suitable for use with spout top FIBC bags. They use gravity to work. To use these machines, you can place the filler on top of an open bulk bag, and the filler will pass through the discharge hose to put the material into the bag below. You can change the flow rate according to the needs of speed or accuracy.

Conveyor Loaders: These more sophisticated machines allow users to move products horizontally, not just down. Therefore, they are usually custom-designed for specific facilities, taking into account the precise layout of the facility. They also help to reduce the labor of employees, because they move the product to the location where it needs to be filled like a conveyor belt. With these loaders, employees will not need to spend time from above the loaders or risk injury from falls.

Pneumatic systems: Pneumatic systems are much more complex, and they are ideal for a wide range of workplaces that require a very comprehensive fibc loading solution. They use industrial-scale vacuum systems and pressurized blowers to set up moving materials throughout the facility and enter the waiting bulk bags.

Lining and coating materials:

dazi's FIBC bag is made of polypropylene woven fabric. Therefore, the most basic bags have gaps naturally.

When customers need to package some fine chemicals or other powder products, we have to coat the base fabric. The FIBC bag that can be used after the film is coated can play a role of moisture-proof and leak-proof, so as to meet the needs of customers.

Sometimes, you also need PP lining, which can prevent the product from being damp and contaminated.

What's new

Time of issue : 2024-05-06

Time of issue : 2024-05-03

Time of issue : 2024-04-30

Time of issue : 2024-04-27

Have questions? We have answers !

Hi,Create an environmentally friendly production enterprise

Contact us

Tel:0086-0379-67215688

Telphone:+86 17395927477

Email:sales@dazisuye.com

Web:https://www.dazisuye.com

Add:Nanlicun Town Industrial park,xin'an County,luoyang,471800,China

放样式的

放样式的

© Luoyang Dazi Plastic Industry Co., Ltd. Powerby: :300.cn