Homopolymer polypropylene random copolymer polypropylene and block copolymer polypropylene

- Categories:News

- Author:

- Origin:

- Time of issue:2022-08-20 08:46

- Views:

(Summary description)PP is versatile, lightweight, low-density, sustainable.

Homopolymer polypropylene random copolymer polypropylene and block copolymer polypropylene

(Summary description)PP is versatile, lightweight, low-density, sustainable.

- Categories:News

- Author:

- Origin:

- Time of issue:2022-08-20 08:46

- Views:

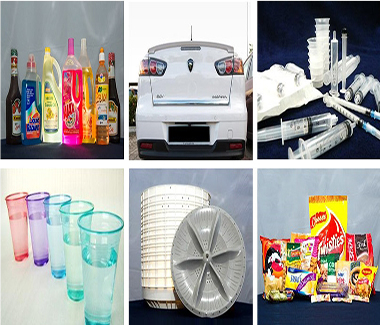

PP is versatile, lightweight, low-density, sustainable.

A wonderful, but confusing thing about PP is that there are several different grades of the same polymer, and no two resins behave the same. On the one hand, this is great because it gives us the opportunity to customize the plastic sheet formulation according to the customer's application; but on the other hand, it may cause confusion about which grade of PP is best for which application. So what is the difference? To provide some guidance, we have compiled a basic guide to help you distinguish the three main levels of PP. Keep reading to learn more!

PP is a semi-crystalline polymer, which is hazy in its natural state due to the presence of crystals. The general characteristics of PP are higher stiffness at lower density, high temperature resistance, and excellent strength-to-weight ratio.The three main grades of PP resin allow to improve specific properties, depending on the composition of the polymer chain:

Homopolymer polypropylene

Homopolymer PP can be considered as the most basic grade of PP resin. This grade of PP resin has stronger rigidity and good high temperature resistance, making it particularly suitable for high temperature applications, such as hot filling and microwave applications or steam sterilization applications. However, the price of this is lower impact resistance, especially at low temperatures. Therefore, it is not recommended to apply homopolymer resins to freezer compartments or other applications where materials will experience extremely low temperatures for a long period of time. Other characteristics of this grade of PP resin include high melting point leading to excellent stiffness, superior scratch resistance, and good chemical resistance to most inorganic acids, alkalis and salts. In addition, this grade of PP resin has strong resistance to environmental stress cracking when it comes in contact with alcohols, esters, detergents or polar hydrocarbons.

Want to find a professional supplier of homopolymer polypropylene? Please contact Polypvc.

Random copolymer polypropylene

Random copolymer PP resin is obtained by modifying the polymer chain by adding a random chain of ethylene between PP units. Due to the presence of ethylene, the rigidity of the homopolymer resin is sacrificed to a certain extent, but this improves the impact strength and soft feel. In addition, it can also improve heat sealing performance, lower melting point, resist environmental stress cracking, and improve clarity. Random copolymer PP resin also has good chemical resistance to most inorganic acids, alkalis and salts.

Ask PolyPvc for the offer of random copolymer polypropylene

Impact Copolymer Polypropylene (or Block Copolymer PP)

Impact polypropylene resin is similar to random copolymer and is obtained by copolymerizing with ethylene, but the ethylene content of this grade is much higher. This results in a tougher material with excellent impact strength even at low temperatures. For this reason, impact-resistant polypropylene resin is particularly suitable for refrigerator and refrigerator-microwave applications. In the past, the use of impact copolymers required a trade-off in transparency, because traditional impact copolymers could not be clarified even with additives.

Contact PolyPvc to learn more about the copolymer polypropylene.

As a professional supplier of polymer resin, we provide PP, PE, PET, PVC, LDPE, HDPE, ABS etc. We will be very glad to if can get a inquiry from you, and will try our best to be a reliable and long time partner with you.

What's new

Time of issue : 2024-05-03

Time of issue : 2024-04-30

Time of issue : 2024-04-27

Time of issue : 2024-04-24

Have questions? We have answers !

Hi,Create an environmentally friendly production enterprise

Contact us

Tel:0086-0379-67215688

Telphone:+86 17395927477

Email:sales@dazisuye.com

Web:https://www.dazisuye.com

Add:Nanlicun Town Industrial park,xin'an County,luoyang,471800,China

放样式的

放样式的

© Luoyang Dazi Plastic Industry Co., Ltd. Powerby: :300.cn