shipping method of quality Polypropylene

- Categories:Polypropylene film News

- Author:

- Origin:

- Time of issue:2023-05-18 14:11

- Views:

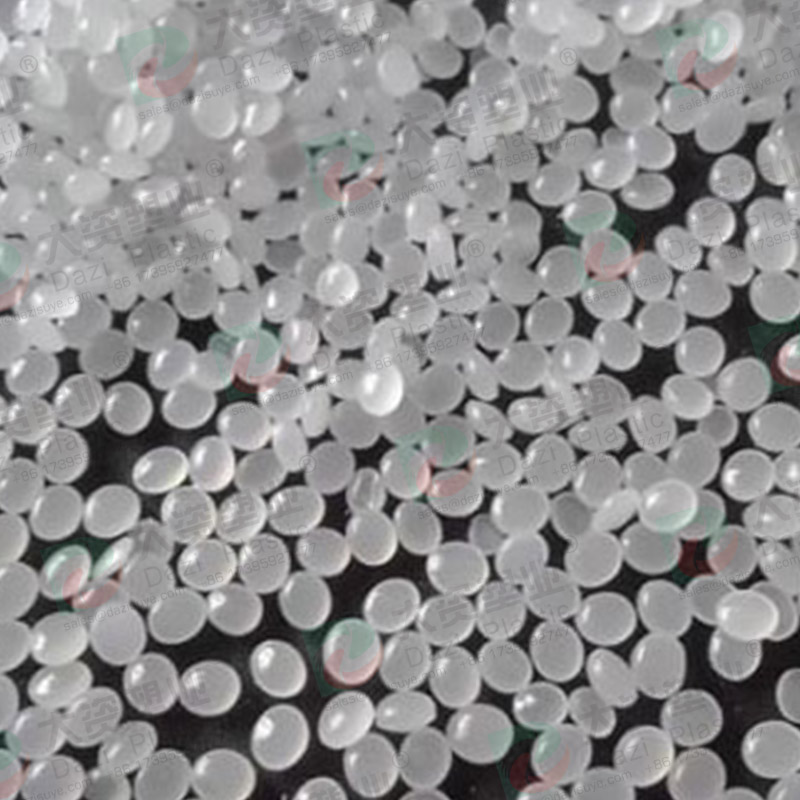

(Summary description)quality Polypropylene is a common plastic material widely used in the manufacture of various products such as bottle caps, food packaging, ropes and more.

shipping method of quality Polypropylene

(Summary description)quality Polypropylene is a common plastic material widely used in the manufacture of various products such as bottle caps, food packaging, ropes and more.

- Categories:Polypropylene film News

- Author:

- Origin:

- Time of issue:2023-05-18 14:11

- Views:

quality Polypropylene is a common plastic material widely used in the manufacture of various products such as bottle caps, food packaging, ropes and more. Since quality Polypropylene is easily affected by factors such as temperature, pressure, and extrusion during transportation, special attention needs to be paid to its packaging and storage methods during transportation. This article will introduce the transportation method of quality Polypropylene from the following aspects.

1. Packaging

quality Polypropylene needs to use proper packaging during transportation to ensure its quality. Packaging should be packaged in special quality Polypropylene bags or rolls, and materials with certain strength and pressure resistance should be used to make packaging. When packing, quality Polypropylene needs to be put into the core and wound tightly to avoid extrusion and deformation during transportation. At the same time, when choosing packaging, it is necessary to consider its moisture-proof, anti-static and anti-ultraviolet properties to ensure its quality and integrity.

2. Temperature control

quality Polypropylene is sensitive to temperature, so special attention should be paid to controlling its temperature during transportation. The transportation temperature should be controlled according to the melting point and processing temperature of quality Polypropylene itself. Generally, when the temperature is lower than the melting point of quality Polypropylene, it can maintain better shape and performance. Therefore, during transportation, air permeability should be increased, temperature and humidity should be reduced, and harsh weather conditions such as sun and rain should be avoided to avoid damage to quality Polypropylene.

3. Shipping method

When choosing the transportation method of quality Polypropylene, it needs to be considered comprehensively based on factors such as its quality, quantity and destination. Usually, transportation by car or boat is the more reliable and common method. Before transportation, quality Polypropylene goods should be weighed, recorded and sealed for reference in follow-up work.

4. Storage

After transportation, quality Polypropylene should be stored in a dry, dark and ventilated warehouse. It should be placed at a relatively low temperature and protected from any extrusion and deformation. In the storage process, it is also necessary to detect and update the packaging materials in time for long-term storage.

To sum up, quality Polypropylene, as a deformable and sensitive plastic material, requires special packaging and protection before transportation and storage. At the same time, it is necessary to pay attention to the transportation temperature, control the humidity of the environment, keep it dry and ventilated during storage, and select materials for packaging according to the requirements of moisture-proof, anti-static and anti-ultraviolet rays. These measures will help ensure that quality Polypropylene maintains good shape and performance during shipping and storage.

What's new

Time of issue : 2024-04-18

Time of issue : 2024-04-15

Time of issue : 2024-04-12

Time of issue : 2024-03-25

Have questions? We have answers !

Hi,Create an environmentally friendly production enterprise

Contact us

Tel:0086-0379-67215688

Telphone:+86 17395927477

Email:sales@dazisuye.com

Web:https://www.dazisuye.com

Add:Nanlicun Town Industrial park,xin'an County,luoyang,471800,China

放样式的

放样式的

© Luoyang Dazi Plastic Industry Co., Ltd. Powerby: :300.cn